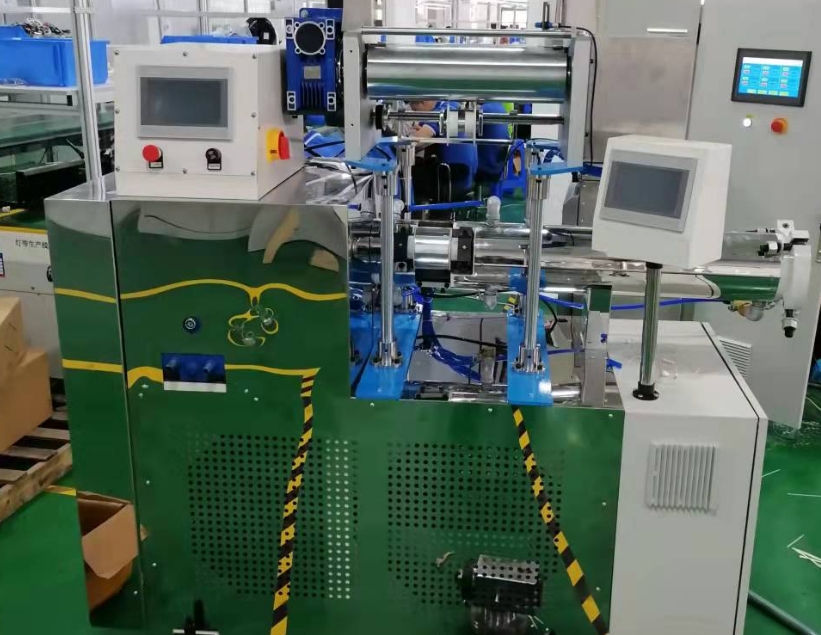

Automatic Feeder

It is used for automatic feeding during silicone rubber extrusion production, which can save labor and ensure the consistency and uniformity of feeding.

·Equipment Description

It is used for automatic feeding during silicone rubber extrusion production, which can save labor and ensure the consistency and uniformity of feeding.

·Technical characteristics

·It adopts double-roller rolling feeding, and the roller is plated with hard luo, which has good wear resistance.

·The roller can be cooled by water, and there is no dead angle for cooling.

·It has the functions of roller material shortage alarm, extruder material breaking alarm and glue overflow alarm in the feeding state of the extruder, which can automatically adjust the speed of roller blanking according to the glue overflow or material breaking situation, and automatically match the production speed of the extruder.

·Using an aviation plug with a single bus, the wiring is convenient and fast, and the appearance is neat.

·It adopts high-speed data transmission mode, and the control is sensitive and the response is fast.

·The overall height is adjustable, which can adapt to extruders of different specifications and manufacturers.

| type | 160型 | 180型 |

| Roller diameter | 160MM | 180MM |

| Gearbox specifications | NMRV63-NMRV90 | NMRV063-NMRV130 |

| Motor power | 3KW Inovance servo motor | 3KW Inovance servo motor |

| Form of control | Mitsubishi PLC + 7-inch Kunlun touch screen | Mitsubishi PLC + 7-inch Kunlun touch screen |

| Suitable models | Φ30、Φ50、Φ65、Φ75 | Φ90、Φ120 |

| Maximum feeding capacity | 15-20 | 20-30 |

| Weight | 200KG | 300KG |

| Dimensions (LxWxH) | 1040*850*500MM | 1160*880*590MM |